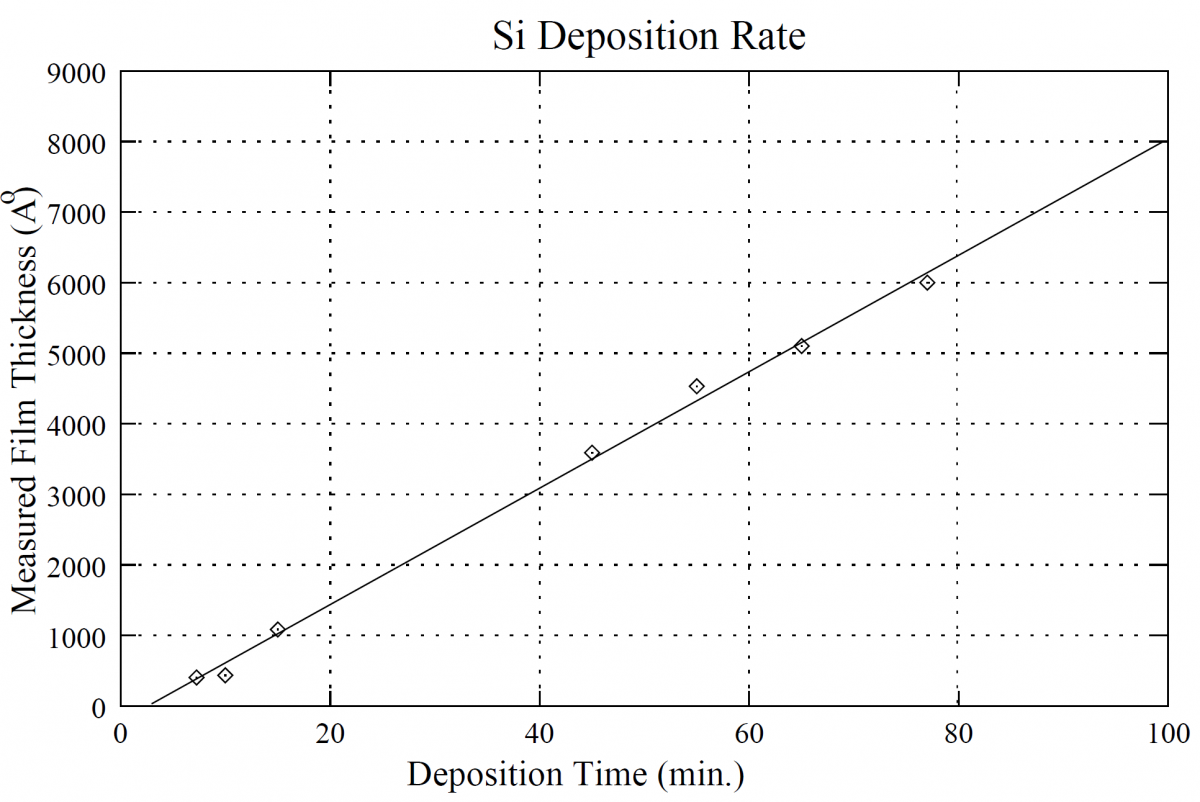

The substrate temperature is slowly increased to $\sim400^\circ\textrm{C}$. Once the substrate temperature has equilibrated, the thermal evaporation of Si begins from an electron beam evaporator at $\sim1.38$ Å/s (Fig. 4.6). The diffusion length of Si in Al at $400^\circ\textrm{C}$ is $1.4\mu\textrm{m}$[1]. Therefore, since $\theta_{\textrm{Al}} \t 2.0\mu\textrm{m}$ in most cases, the rate of the SMME growth front is expected to be nearly equal to the deposition rate of diffusors at the mediator surface.

The surface structure is monitored by RHEED during Si deposition. The RHEED patterns obtained are compared to those from the initial mediator surface immediately after Al deposition. If Si has been successfully incorporated in the mediator film, the RHEED pattern should indicate an Al mediator surface. During Si deposition the surface is observed by RHEED to change, indicating correct diffraction beam location on the substrate with respect to an area of Si deposition coverage.

|

Figure 4.6. Deposition Rate of Si Diffusor. These data are collected from various reliable candidate samples as measured by a stylus profilometer. The measured average Si growth rate is 1.38 Å/s via electron beam evaporator source ($\textrm{HV} = 9.5 \textrm{keV}$, $I=0.1 \textrm{A}$). |

References

- , “Silicon diffusion in aluminium”, Thin Solid Films, vol. 128, no. 3-4, pp. 217-223, 1985.