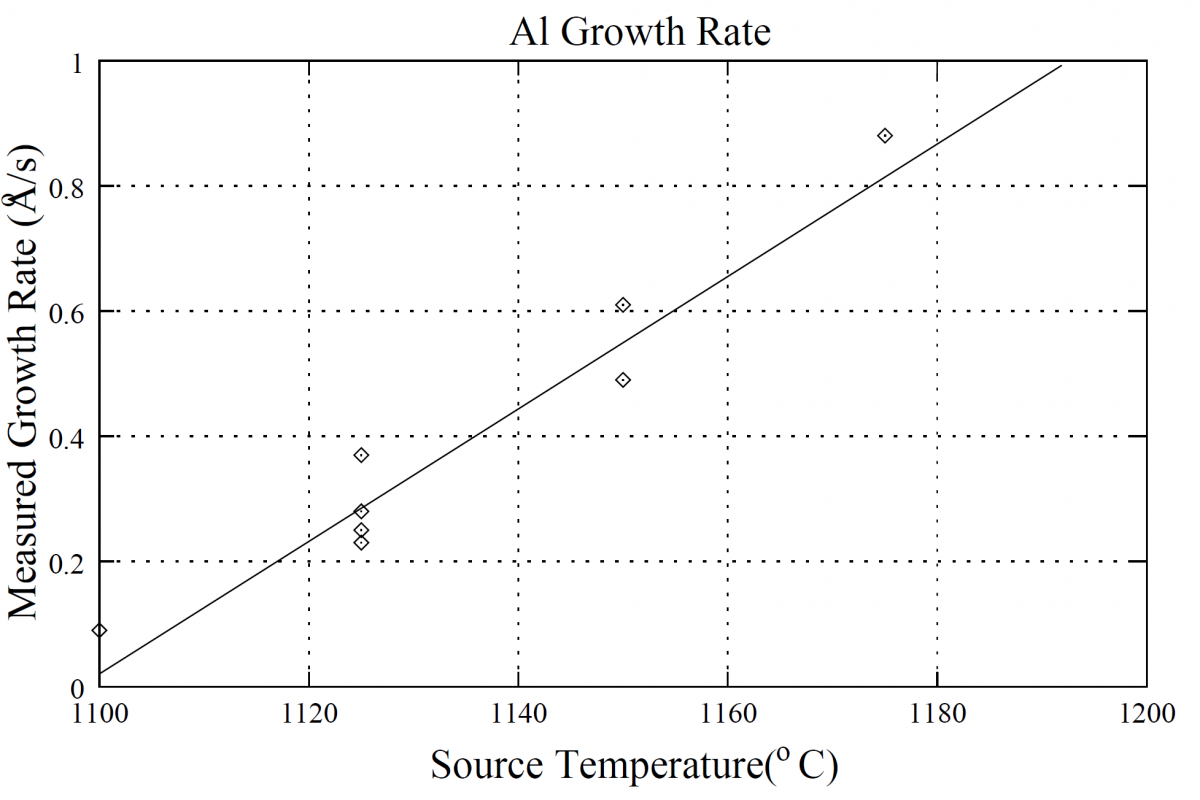

High purity Al is thermally evaporated from a (Knudsen) effusion cell ($1100^\circ \textrm{C} \lt T_{\textrm{Al}} \lt 1175^\circ \textrm{C}$) at room temperature for an appropriate time to provide sufficient mediator coverage of the oxide ($\theta_{\textrm{Al}} \gt \theta_{\textrm{ox}}$ ). The growth rate of Al varies from 0.2 to 0.9 Å/s in the source temperature range (Fig. 4.4).

|

Figure 4.5. Deposition Rate of Al Mediator. These data are collected from various stylus profilometer measurements on only a select few reliable samples. Scattering in the data is attributed to relative surface roughness. |

RHEED analysis is performed during Al mediator deposition to monitor any changes in Al orientation as a function of film thickness. Once the deposition is complete, a final RHEED study is performed to record the Al surface crystallinity and orientation. As well, to ensure the consistency and accuracy of RHEED measurements, a dimensional comparison is made of the RHEED pattern provided by the cleaned, reconstructed, Si substrate, with the deposited Al mediator surface RHEED pattern. The RHEED pattern dimensions represent reciprocal lattice vectors, hence,

| $$\frac{R_{\textrm{Al}}}{R_{\textrm{Si}}}=\frac{d_{\textrm{Si}}}{d_{\textrm{Al}}}=1.34,$$ | (4.1) |

where, $R$ is the $k$-space (reciprocal space) radius measured directly from the RHEED pattern, and $d$ is the real space lattice distances (Table 1.1) of respective crystals.