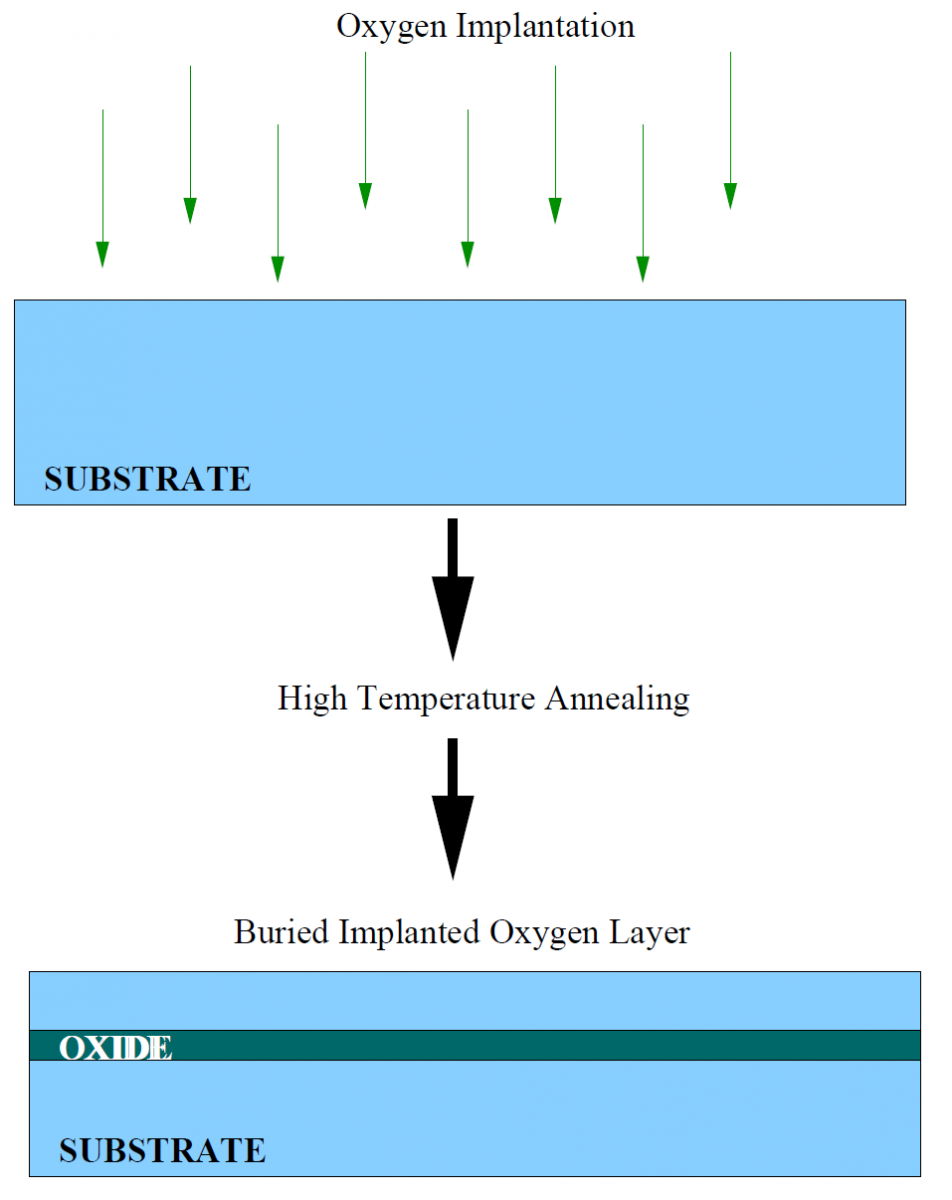

The most widely used SOI wafer fabrication technology[1][2][3][4] (Fig. 3.3) is separation by implanted oxygen (SIMOX). High energy oxygen ions are implanted into the silicon wafer and diffuse to form a buried layer of oxygen. The result of this first step is a severely damaged device layer of silicon above the oxygen. The wafer is correspondingly annealed for several hours at high temperature in an attempt to remove defects from the device layer and promote the formation of stoichiometric silicon dioxide (SiO2). Film thicknesses are selectively defined by the oxygen ion implantation energy.

SIMOX is useful for SOI wafer manufacturing. However, once the first device layer has been fabricated, the second device layer also requires insulation. The first device layer may contain materials that cannot withstand annealing temperatures required by the SIMOX process. SMM-SOI is anticipated to provide fewer defects in the device layer than SIMOX without the need for high temperature annealing and other costly fabrication requirements. Therefore, SMM-SOI becomes a convenient fabrication technology for use in devices that require low-temperature, device-quality SOI fabrication.

|

Figure 3.3. Separation by Implanted Oxygen (SIMOX) Process. High energy oxygen ions are implanted into a Si wafer. The wafer is annealed at high temperatures to form a buried stoichiometric SiO2 film and correct any defects in the device layer caused by the implantation of large oxygen ions. |

References

- , “SIMOX -- A new challenge for ion implantation”, Nucl. Instrum. Methods Phys. Res. B, vol. 96, no. 1-2, pp. 420-424, 1995.

- , “The development of CMOS/SIMOX technology”, Microelectronics Engineering, vol. 28, no. 1-4, pp. 423-430, 1995.

- , “ Buried-oxide layer formation by high-dose oxygen-ion implantation into Si wafers: SIMOX (separation by implanted oxygen) ”, Appl. Surf. Sci, vol. 85, pp. 259-264, 1995.

- , “Evolution and Future Trends of SIMOX Material”, MRS Bulletin, vol. 23, pp. 25-29, 1998.