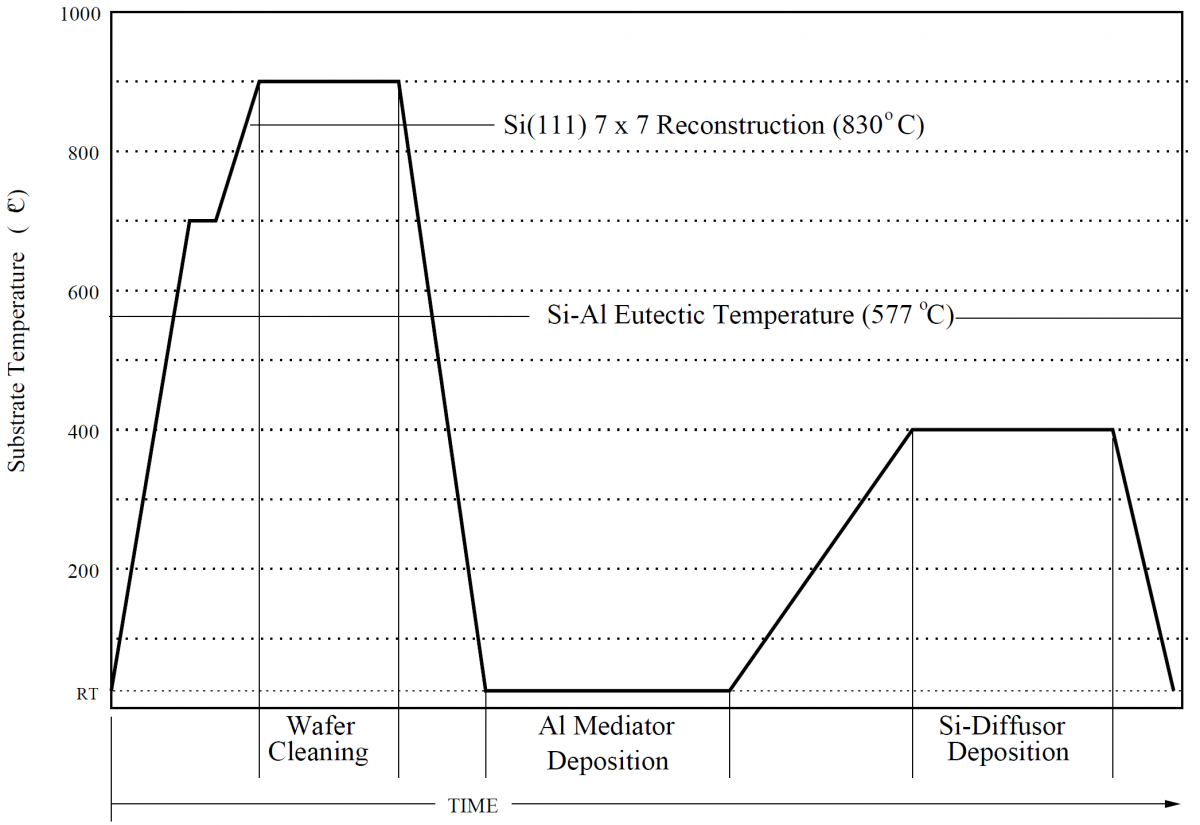

Final wafer cleaning is essential to epitaxial growth of high quality crystalline semiconductor and metal thin films. After the vacuum chamber and components have been properly prepared, the wafer is inserted into the UHV-MBE chamber via loadlock (section B.4.3) and analysis chamber (section B.4.2)and placed in the substrate holder for heating. Resistive heating is provided by a resistively heated grid of thin tantalum strips from the back of the wafer (Fig. 4.7). The temperature is incrementally increased and held at $900^\circ \textrm{C}$ for 20-30 minutes (Fig. 4.4) for complete desorption of native oxides present at the substrate surface in the seeding areas. This largely removes any surface defects and contaminants from the seeding areas.

|

Figure 4.4. Epitaxial Deposition Process Map. The substrate is first heated to $900^\circ \textrm{C}$ to induce appropriate surface reconstruction. Al mediator deposition proceeds at room temperature, followed by Si diffusor deposition at $\sim400^\circ\textrm{C}$ (below the eutectic temperature of Al-Si). |

To ensure proper Si wafer surface cleaning, an in situ RHEED investigation is performed to verify the atomic structure of the surface. By heating the wafer to $900^\circ\textrm{C}$ both orientations, Si(111) and Si(100), are heated beyond the temperature at which surface reconstruction occurs. When heated to $900^\circ\textrm{C}$ then cooled through $830^\circ \textrm{C}$, the Si(111) surface reconstructs to $7\times 7$ and remains intact at room temperature. Si(100) reconstructs to $2\times 2$ once all surface contaminants are thermally removed.

Once the appropriate surface reconstruction has been observed by RHEED, the wafer is cooled to room temperature while maintaining the low energy surface reconstruction. Due to the ultrahigh vacuum in the MBE system, the rate of surface contamination by residual gases is very slow. This ensures a clean surface during deposition. At this point, an additional measure of vacuum cleanliness is exploited. The main deposition chamber consists of a shroud that lines the chamber walls. This shroud is cooled by liquid nitrogen during deposition, trapping residual contaminants on the chamber walls and reducing the base pressure by an order of magnitude.

During substrate cleaning by thermal desorption the vacuum chamber pressure may rise an order of magnitude. Once the substrate has returned to room temperature, the chamber pressure likewise returns to its base pressure. An additional RHEED investigation is conducted at room temperature to ensure cleanliness. The wafer is then ready for epitaxial deposition.