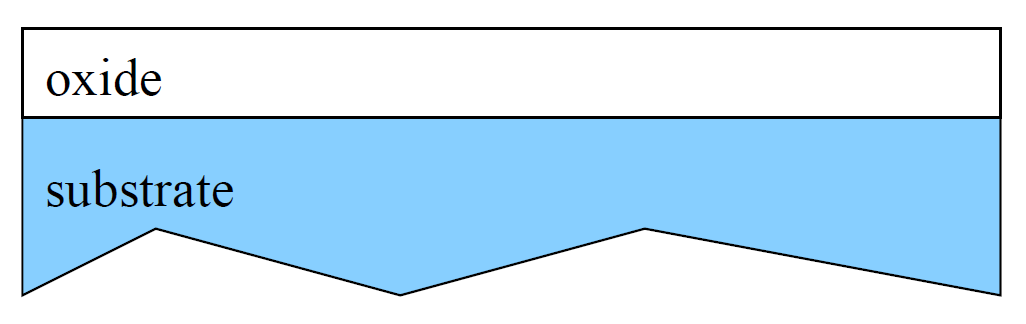

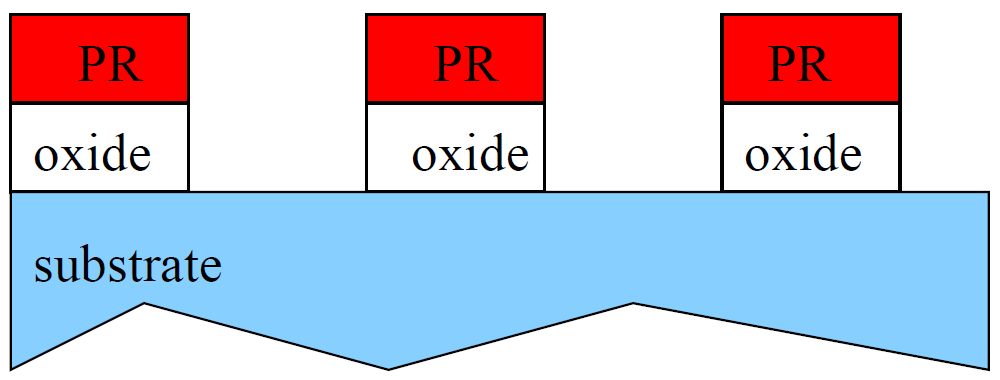

The wafers are loaded into a thermal oxidation furnace. The rate of oxidation in the nitrogen-ambient environment of the furnace is controlled by the furnace temperature (typically $1100 - 1150^\circ \textrm{C}$) and exposure time. Oxide thicknesses, $\theta_{\textrm{ox}}$, of 250, 500 and 1000 Å are prepared for the current investigation (Fig. 4.1a).