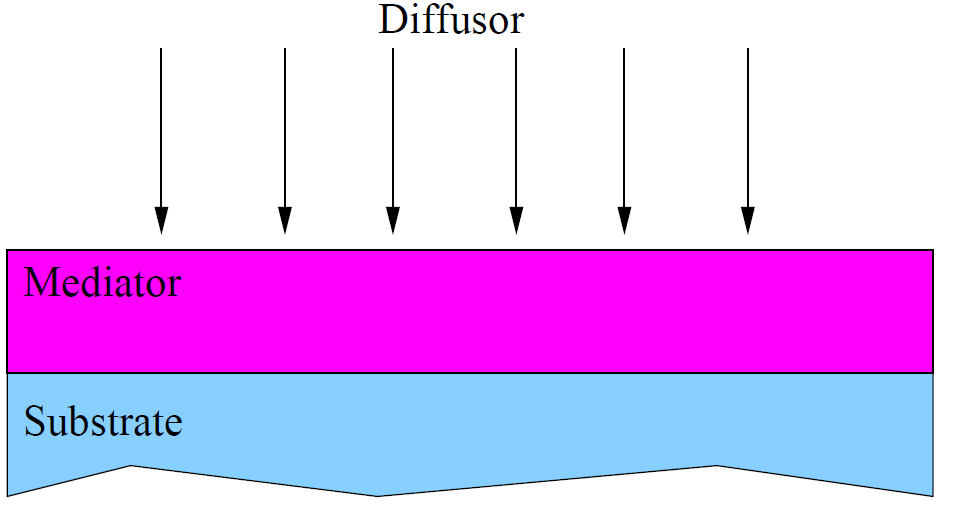

The SMME device structure includes a substrate, mediator, and diffusing element herein referred to as a diffusor (Fig. 2.3a). An understanding of the interrelationships among these three components is central to the implementation of the SMME process to a given system of materials.

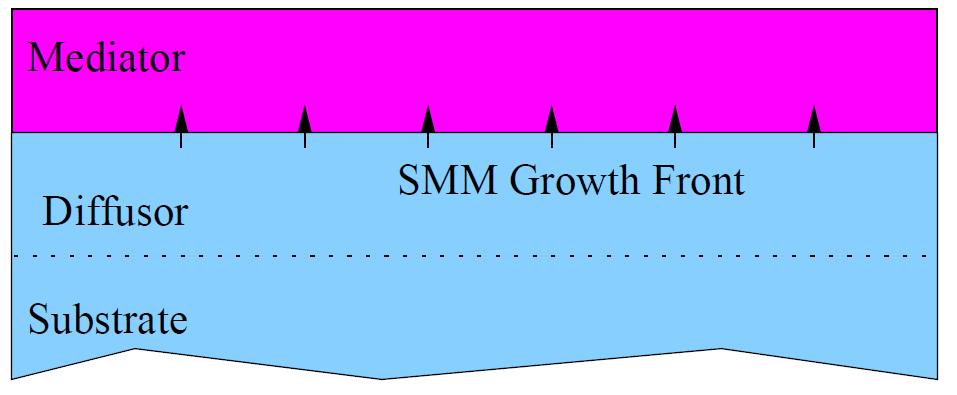

Figure 2.3. The Basic SMME Model includes a) a substrate, mediator, and diffusor. b) The result of SMME is a substrate/diffusor/mediator sandwich containing an atomically abrupt diffusor/mediator interface and a virtually unchanged mediator thin film. |

First, the surface of an appropriate substrate is treated to induce the necessary surface conditions that permit proper crystalline (or polycrystalline) growth of the solid mediator thin film. Among the list of necessary surface conditions are cleanliness, surface reconstruction, and surface lattice site energies compatible with diffusor atoms (typically lower than the energy of bulk mediator lattice sites to allow for successful incorporation of diffusors).

The solid mediator thin film is epitaxially deposited to a given thickness at an appropriate substrate temperature. The thickness of the mediator film is limited by the diffusion length of the diffusor atom in the mediator bulk at the given substrate temperature during diffusor deposition. While a single- and double-domain aluminum mediator has been shown to permit successful incorporation of silicon diffusors[1], a polycrystalline mediator should not be ruled out as a potential mediator material.

Once the mediator has successfully grown, the diffusor is deposited at a substrate temperature that provides an appropriate diffusion length in the mediator bulk and the fewest possible interactions (e.g. electrochemical) of the two materials.

The final structure of the SMME model (Fig. 2.3b) includes a buried single crystalline film made of diffusor atoms. The newly formed diffusor-mediator interface has been shown, in the specific diffusor-mediator combination of Si-Al, to be atomically abrupt[2]. This feature of SMME is anticipated to result from several diffusor-mediator combinations. An abrupt interface is necessary to prevent various unwanted electronic phenomena like spiking[3][4].

An original investigation reported "spontaneous'" growth of a buried single crystalline Si(111) thin film with little or no measurable damage to the c-Al(111) mediator film. This can be attributed to the long diffusion length of Si in Al due to the lack of interactions of Si and Al atoms at the deposition temperature. The remaining mediator can be immediately used for additional fabrication steps or utilized as part of the final device structure.

References

- , “Epitaxial growth of Al on Si by thermal evaporation in ultra-high vacuum: growth on Si(100)2x1 single and double domain surfaces at room temperature”, Surface Science, vol. 236, 1990.

- , “Solid-Metal Mediated Molecular Beam Epitaxy (SMM-MBE) of Si(111) at a Buried Inteface: A New Epitaxial Growth Method”, in 42nd National AVS Symposium, Minneapolis, MN, 1995.

- , The Science and Engineering of Microelectronic Fabrication. Oxford University Press, 1996.

- , Electronic Thin Film Science for Electrical Engineers and Materials Scientists. Macmillan, 1992.